Quick Exhaust Valves

Home » Our Products » Pneumatic Accessories » Pressure Gauges » Quick Exhaust Valves

- Our Products

Quick Exhaust Valves

- get in touch

Reach Out to Our Team Today for Customized Industrial Valve Assistance and Inquiries

At Valvomatic Industries, we value open communication and are always here to assist with any questions or inquiries you may have. Whether you’re looking for more information about our products, need technical support, or have specific requirements for your project, our dedicated team is ready to help.

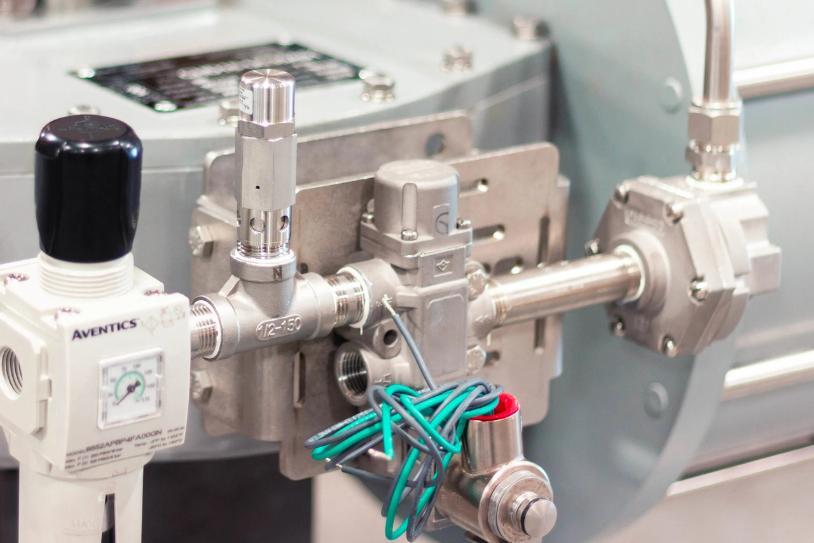

Quick Exhaust Valves are pneumatic devices used to rapidly release air or gas from a system, allowing for a quick reduction in pressure. They are commonly used in applications where fast exhaust of air or gas is required, such as in pneumatic systems, air cylinders, and pneumatic tools. Quick Exhaust Valves can be found in various industries, including manufacturing, aerospace, and automotive.

Quick Exhaust Valves typically consist of a valve body, a poppet, and a spring. When the valve is closed, the poppet is held in place by the spring, preventing air or gas from escaping. When the valve is opened, the poppet is released, allowing air or gas to rapidly flow out of the system. Quick Exhaust Valves can be actuated manually or pneumatically, and may be designed for specific pressures and flow rates. They are often used in combination with other pneumatic devices, such as air cylinders and regulators, to create complex systems.

Features of Quick Exhaust Valves

- Rapid Exhaust

- High Flow Rates

- Long Life

- Pneumatic Actuation

- Compact Design

- High Pressure

Applications of Quick Exhaust Valves

- Pneumatic Cylinder Speed Control

- Robotics and Automation

- High-Speed Pressing and Stamping

- Clamping and Gripping Systems:

- Pneumatic Braking Systems

- Safety Circuits

Specifications of Quick Exhaust Valves

| Valve Type | Quick Exhaust Valve (often with a specific sub-type, e.g., "Inline" or "Ported") |

| Port Size/Connection | 1/8" NPT, 1/4" NPT, 3/8" NPT, M5, G1/8, G1/4, push-in fittings (various sizes) |

| Operating Pressure | 0 to 10 bar (0 to 145 psi), Specific ranges may vary by model. Important to check for the specific valve! |

| Operating Temperature | -10°C to +60°C (14°F to 140°F), ranges will vary with materials and model |

| Flow Rate (Cv/Kv) | Cv = 0.5 to 2.0 (US customary units), Kv = values in metric units, will vary significantly based on port size and design |

| Effective Area | A specific cross-sectional area; influences the valve's ability to quickly exhaust air. Usually, in mm^2 or in^2. |

| Response Time | Milliseconds (ms). Fast response times are a key feature. Will vary based on pressure and flow conditions. |

| Mounting | Inline, Sub-base, Panel Mount, Threaded |

| Media | Compressed Air, Inert Gases, (may depend on materials of construction; compatibility is essential) |

| Body Material | Aluminum, Brass, Stainless Steel (affects corrosion resistance and pressure ratings) |

| Seal Material | NBR (Nitrile), FKM (Viton), other synthetic rubbers or polymers (impacts temperature and media compatibility) |

| Weight | Varies based on size and materials (e.g., 0.1 kg to 0.5 kg) |

| Dimensions | Specific dimensions in mm or inches (length, width, height) - critical for installation! |

| Optional Features | Silencers, Speed Control Adjustments, integrated fittings. These vary widely based on the specific product. |

| Certifications/Standards | CE, RoHS compliant, other industry-specific standards (check data sheet). |

| Model Number/Series | Critical! This is how you identify the exact valve you are interested in. (Example: QE-123-B or QEV-Series-500) |