Thermostatic Steam Trap

Home » Our Products » Steam Traps » Thermostatic Steam Trap

- Our Products

Thermostatic Steam Trap

- get in touch

Reach Out to Our Team Today for Customized Industrial Valve Assistance and Inquiries

At Valvomatic Industries, we value open communication and are always here to assist with any questions or inquiries you may have. Whether you’re looking for more information about our products, need technical support, or have specific requirements for your project, our dedicated team is ready to help.

- our products

download brochure

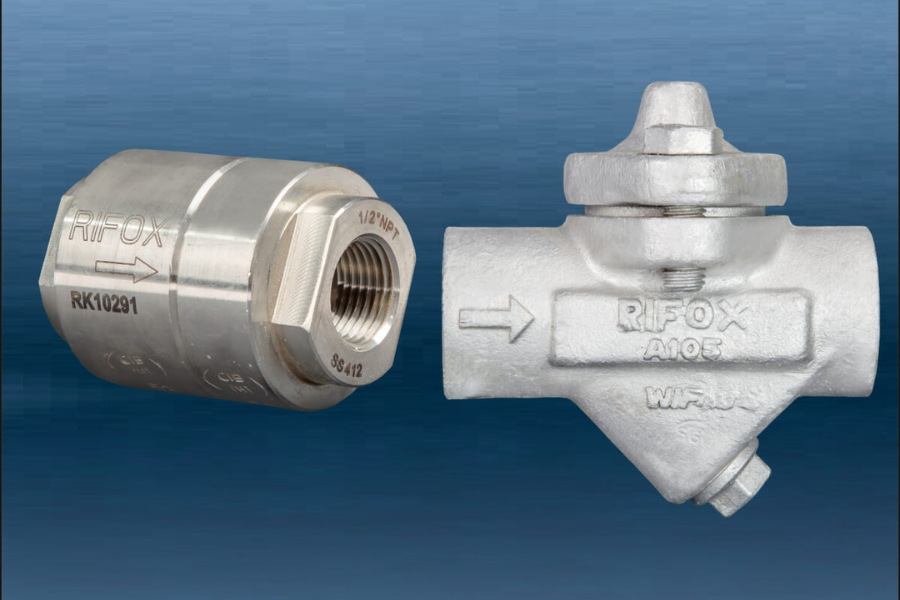

A thermostatic steam trap is a type of automatic valve used in steam systems to remove condensate (water formed by the condensation of steam) and non-condensable gases (like air) while preventing the escape of live steam. They operate based on the temperature difference between steam and condensate. Inside the trap, a temperature-sensitive element, such as a bimetallic strip or a balanced-pressure capsule, expands and contracts with temperature changes.

When steam enters the trap, the element heats up and closes the valve, preventing steam from escaping. As condensate accumulates and cools, the element contracts, opening the valve to discharge the condensate. The trap’s design allows it to efficiently remove condensate at or near steam temperature, improving the efficiency of the steam system by preventing steam loss and maintaining optimal heat transfer. Different designs offer varying performance characteristics, making them suitable for various steam system applications.

Features

- Balanced Pressure Operation

- Sensitivity to Temperature

- Wide Operating Pressure Range

- Freeze Resistance

- Fast Response to Load Changes

- Suitable for Superheated Steam

Applications

- Process Steam Systems

- HVAC Systems

- District Heating Systems

- Specific Industries

- Chemical processing

- Pulp and paper

Specifications

| Type | Volumetric Thermostatic (Balanced-Pressure) |

| Body Material | Cast Iron, Ductile Iron, Cast Steel, Stainless Steel (depending on application) |

| Internal Components | Stainless Steel (typically capsule and valve components) |

| Connection Types | Screwed (NPT, BSPT), Flanged (ANSI, DIN, JIS), Socket Weld |

| Orientation | Horizontal or Vertical (check manufacturer's recommendations) |

| Approvals | (CE, ASME, etc. - varies by model and intended market) |

| Maximum Operating Pressure (MOP) | [150-450] psi ([10-30] bar) - varies widely, check specific model |

| Minimum Operating Pressure (MOP) | [0-5] psi ([0-0.3] bar) - some models can operate at near vacuum conditions |

| Maximum Operating Temperature | Depends on the pressure and the saturated steam temperature at that pressure. [450-650]°F ([232-343]°C) - model dependent |

| Discharge Capacity (Condensate) | (lbs/hr or kg/hr) - varies with pressure drop (e.g., at [5-100] psi, different capacities). Published on capacity charts. |

| Operating Temperature Range | Close to saturation temperature of steam. Can be specified to vent air. |

| Subcooling Response | A few degrees below saturation. |

| Nominal Size | [1/2]-inch, [3/4]-inch, [1]-inch (and larger) - depends on capacity requirements |

| Dimensions | Length, Width, Height (in inches or mm) - vary with size and connection type |

| Weight | (lbs or kg) - depends on size and materials |

| Air Venting | Some models offer built-in automatic air venting to remove non-condensable gases. |

| Freeze Protection | Generally good resistance to freezing due to the capsule design, but specific freeze-resistant designs may be available. |

| Maintenance | Relatively easy to maintain. Some traps have replaceable internals (capsule/valve). |

| Materials of Construction | Capsule, valve and seat materials are specific to the application |