Mechanical Steam Trap

Home » Our Products » Steam Traps » Mechanical Steam Trap

- Our Products

Mechanical Steam Trap

- get in touch

Reach Out to Our Team Today for Customized Industrial Valve Assistance and Inquiries

At Valvomatic Industries, we value open communication and are always here to assist with any questions or inquiries you may have. Whether you’re looking for more information about our products, need technical support, or have specific requirements for your project, our dedicated team is ready to help.

- our products

download brochure

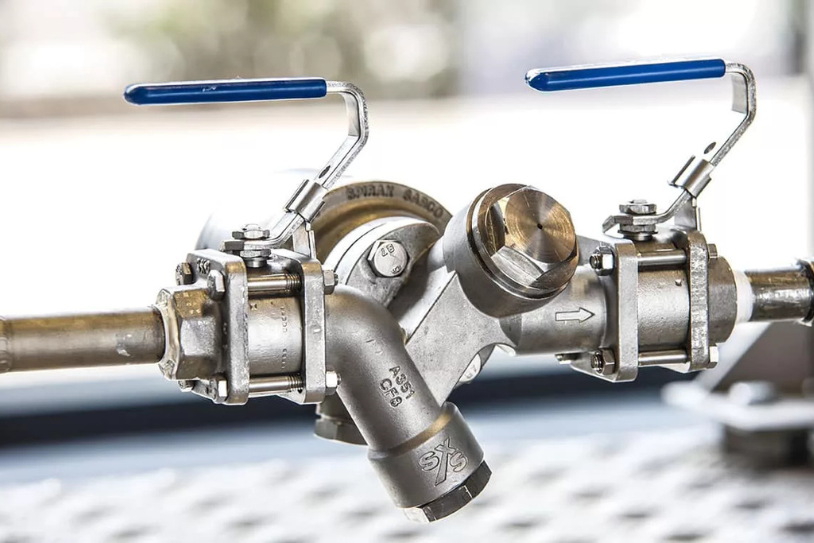

Mechanical steam traps operate based on the difference in density between steam and condensate. These traps utilize a float or bucket mechanism, which responds to the presence of liquid water. As condensate accumulates, the float or bucket rises (or lowers in the case of an inverted bucket), opening a valve to discharge the collected water. This process is repeated continuously, ensuring efficient removal of condensate and preventing steam loss.

In essence, the volumetric displacement of the float or bucket directly controls the valve opening. The float’s position, dictated by the rising water level, dictates the flow rate and response time of the trap. This mechanism offers reliable performance and efficient operation.

Features of Mechanical Steam Trap

- Continuous Condensate Discharge

- Excellent Air Venting

- Ability to Handle Wide Load Variations

- Good Resistance to Water Hammer

- Sensitivity to Steam Loss

- Simplified Operation

Applications of Mechanical Steam Trap

- Steam Distribution Systems

- Boilers and Heater Systems

- Power Plant Applications

- Chemical Plant and Refineries

- Oil and Gas Fields

- Paper Mill and Textile Industry

Specifications of Mechanical Steam Trap

| Trap Type | Float Trap, Inverted Bucket Trap |

| Operating Principle | Volumetric: Uses a float or inverted bucket to sense condensate level and control valve opening/closing. |

| Materials | Body: Cast Iron, Cast Steel, Stainless Steel; Internal Parts: Stainless Steel, hardened stainless steel, etc. |

| Connections | Threaded (NPT, BSPT), Flanged (ANSI, DIN), Welded |

| Pressure Rating (Maximum) | Up to 46 bar (670 psi) or higher, depending on the model. Higher pressures are common in float traps. |

| Pressure Rating (Minimum) | Can operate at very low pressures (close to atmospheric) - this is a key advantage. |

| Temperature Range | Up to 260°C (500°F) or higher, depending on the model. |

| Capacity (Condensate Discharge) | Varies widely. From a few kg/hr to tens of tons/hr, depending on the trap size and pressure differential. |

| Air Venting | Excellent. Automatic air venting is a key characteristic of float traps. Inverted bucket traps vent air as well. |

| Steam Loss | Low, particularly with well-maintained traps. |

| Freeze Protection | Some models are designed with freeze protection features (e.g., with internal steam chambers to keep the condensate hot). |

| Installation | Horizontal or vertical installation (depending on the model), often with a strainer upstream. |

| Maintenance | Relatively easy maintenance, including periodic inspection and cleaning or, in some cases, replacement of internal parts. |

| Size Range | ½" to 4" or larger (connection size). |

| Body Design | Straight-through or angle patterns. |

| Differential Pressure | Up to high delta P ratings, depending on application. |

| Fail-Safe | Closed or open fail-safe mode, depending on the manufacturer and design. |